Content on this page

FloorPlan

- What is synthesis?

- Goals of synthesis

- Synthesis Flow

- Synthesis (input & output)

- HDL file gen. & lib setup

- Reading files

- Design envi. Constraints

- Compile

- Generate Reports

- Write files

- Netlist(.v or .vhd)

- Constraints

- Liberty Timing File(.lib or .db)

- Library Exchange Format(LEF)

- Technology Related files

- TLU+ File

- Milkyway Library

- Power Specification File

- Optimization Directives

- Design Exchange Formats

- Clock Tree Constraints/ Specification

- IO Information File

- import design

- sanity checks

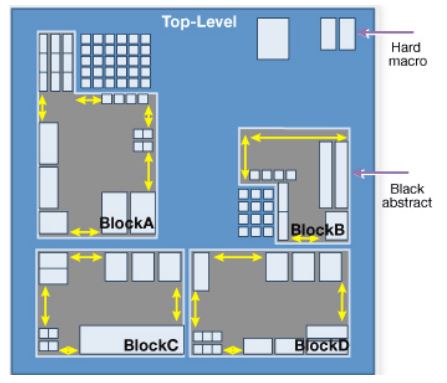

- partitioning (flat and hierarchy)

- objectives of floorplan

- Inputs of floorplan

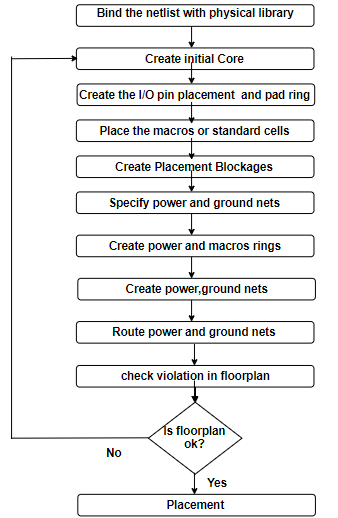

- Floorplan flowchart

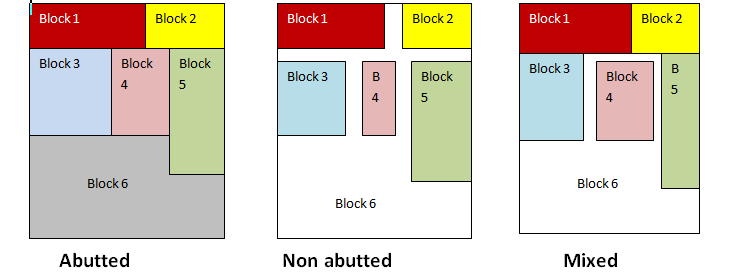

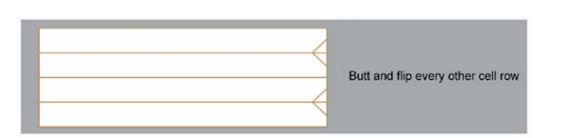

- Floorplan Techniques

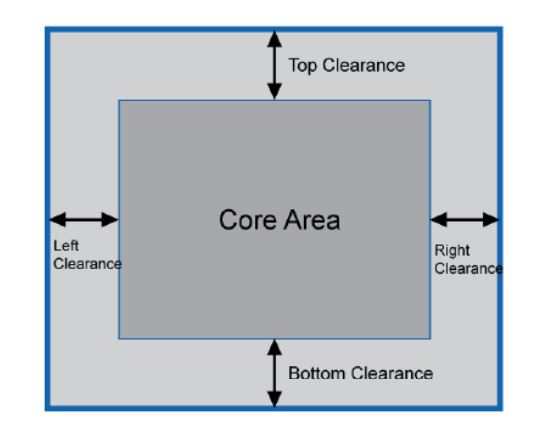

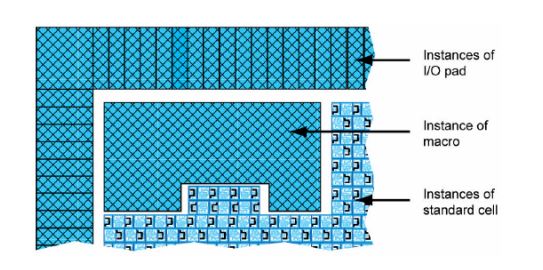

- Terminologies and definitions

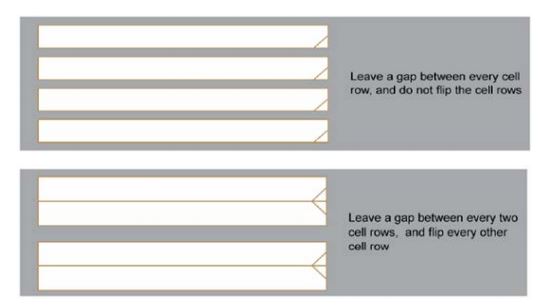

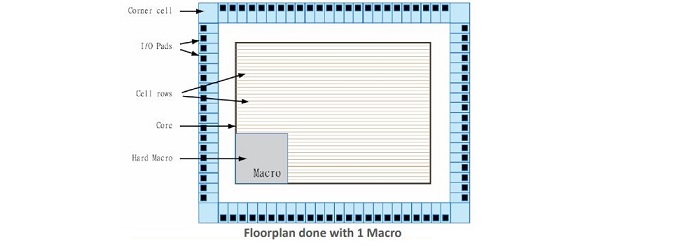

- Steps in FloorPlan

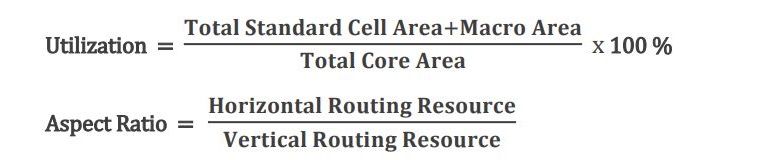

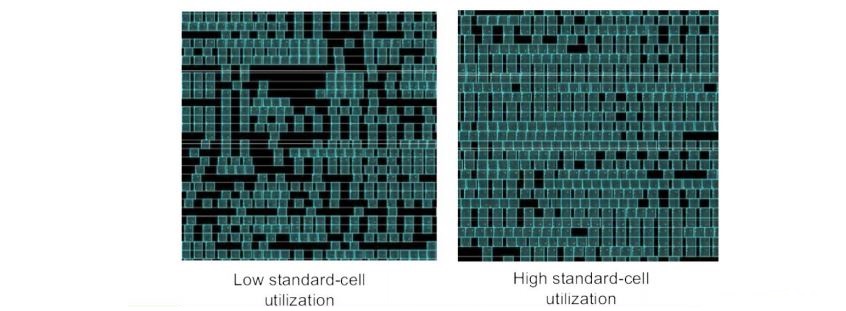

- Utilization

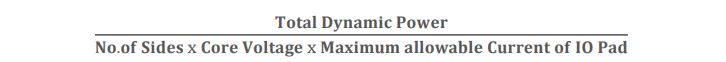

- IO Placement

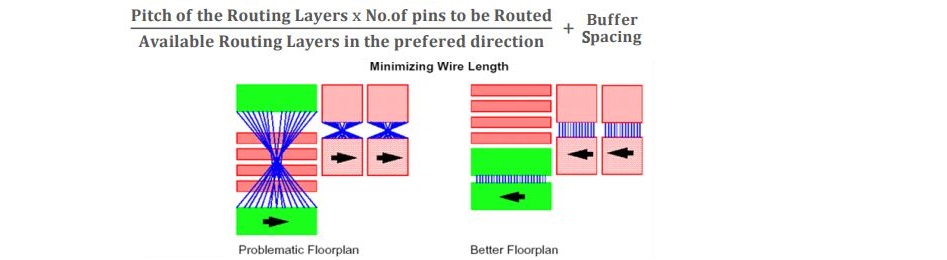

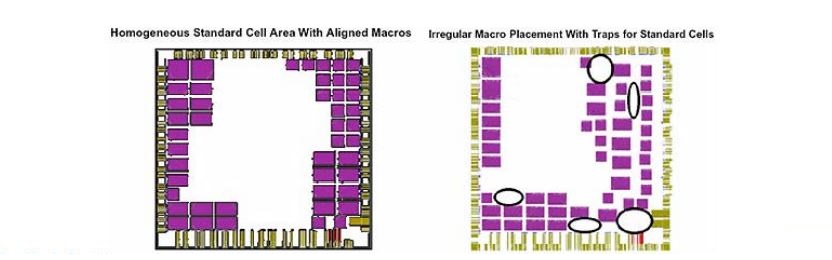

- Macro Placement

- Macro Placement Tips

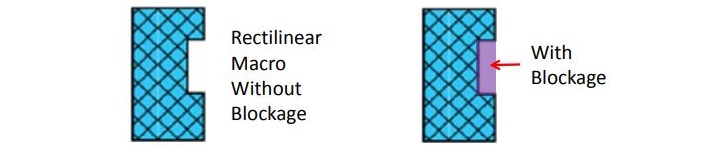

- Blockages (soft,hard,partial)

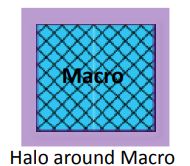

- Halo/keepout margin

- Issues arises due to bad floor-plan)

- FloorPlan Qualifications

- FloorPlan Output

- levels of power distribution

- Power Management

- Powerplanning involves

- Inputs of powerplan

- Properties of ideal powerplan

- Power Information

- PowerPlan calculations

- Sub-Block configuration

- fullchip configuration

- UPF Content

- Isolation Cell

- Level Shifters

- Retention Registers

- Power Switches

- Types of Power dissipation

- IR Drop

- Electromigration

- Pre-Placement

- Pre-Placement Optimization

- Placement

- Placement Objectives

- Goals of Placement

- Inputs of Placement

- Checks Before placement

- Placement Methods(Timing & Congestion)

- Placement Steps

- Placement Optimization

- Placement Qualifications

- Placement Outputs

- Pre-CTS Optimization

- CTS

- Diff b/w HFNS & CTS

- Diff b/w Clock & normal buffer

- CTS inputs

- CTS Goals

- Clock latency

- Clock problems

- Main concerns for Clock design

- Clock Skew

- Clock Jitter

- CTS Pre requisites

- CTS Objects

- CTS Flow

- Clock Tree Reference

- Clock Tree Exceptions

- CTS Algorithm

- Analyze the Clock tree

- Post CTS Optimization

- CTS Outputs

- Importance of Routing as Technology Shrinks

- Routing Objectives

- Routing

- Routing Inputs

- Routing Goals

- Routing constraints

- Routing Flow

- Trial/Global Routing

- Track Assignment

- Detail/Nano Routing

- Grid based Routing

- Routing Preferences

- Post Routing Optimization

- Filler Cell Insertion

- Metal Fill

- Spare Cells Tie-up/ Tie-down

- Diff b/w DTA & STA

- Static Timing Analysis

- main steps in STA

- STA(input & output)

- Timing Report

- Clocked storage elements

- Delays

- Pins related to clock

- Timing Arc

- Timing Unate

- Clock definitions in STA

- Timing Paths

- Timing Path Groups

- Clock Latency

- Insertion Delay

- Clock Uncertainty

- Clock Skew

- Clock Jitter

- Glitch

- Pulse width

- Duty Cycle

- Transition/Slew

- Asynchronous Path

- Critical Path

- Shortest Path

- Clock Gating Path

- Launch path

- Arrival Path

- Required Time

- Common Path Pessimism(CPP/CRPR)

- Slack

- Setup and Hold time

- Setup & hold time violations

- Recovery Time

- Removal Time

- Recovery & Removal time violations

- Single Cycle path

- Multi Cycle Path

- Half Cycle Path

- False Path

- Clock Domain Crossing(CDC)

- Clock Domain Synchronization Scheme

- Bottleneck Analysis

- Multi-VT Cells(HVT LVT SVT)

- Time Borrowing/Stealing

- Types of STA (PBA GBA)

- Diff b/w PBA & GBA

- Block based STA & Path based STA

- Congestion Analysis

- Routing Congestion Analysis

- Placement Cong. Analysis

- Routing Congestion causes

- Congestion Fixes

- Global & local cong.

- Congestion Profiles

- Power Analysis

- Leakeage Power

- Switching Power

- Short Circuit

- Leakage/static Power

- Static power Dissipation

- Types of Static Leakage

- Static Power Reduction Techniques

- Dynamic/Switching Power

- Dynamic Power calculation depends on

- Types of Dynamic Power

- Dynamic Power Reduction Techniques

- IR Drop Analysis

- Types of IR Drop & their methodologies

- IR Drop Reasons

- IR Drop Robustness Checks

- IR Drop Impacts

- IR Drop Remedies

- Ldi/dt Effects

- Design Parasitics

- Latch-Up

- Electrostatic Discharge(ESD)

- Electromigration

- Antenna Effect

- Crosstalk

- Soft Errors

- Sef Heating

- Cells in PD

- Standard Cells

- ICG Cells

- Well Taps

- End Caps

- Filler Cells

- Decap Cells

- ESD Clamp

- Spare Cells

- Tie Cells

- Delay Cells

- Metrology Cells

- IO Pads

- Types of IO Pads

- Delay Calculation

- Delay Models

- Interconnect Delay Models

- Cell Delay Models

- Engineering Change Order

- Post Synthesis ECO

- Post Route ECO

- Post Silicon ECO

- Metal Layer ECO Example

- std cell library types

- Classification wrt density and Vth

- The Discontinuity

- Discontinuity: Classification

- DFM/DFY

- Yield Classification

- Why DFM/DFY?

- DFM/DFY Solution

- Wire Spreading

- metal Fill

- CAA

- CMP Aware-Design

- Redundant Via

- RET

- Litho Process Check(LPC)

- Layout Dependent Effects

- Resolution Enhancement Techniques

- Types of RET

- Optical Proximity Correction(OPC)

- Scattering Bars

- Multiple Patterning

- Phase-shift Masking

- Off-Axis Illumination

- Corners

- Need for corner analysis

- PVT Variations

- Corner Analysis

- PVT/RC Corners

- Temperature Inversion

- Cross Corner Analysis

- Modes of Analysis

- MC/MM Analysis

- OCV

- Derating

- OCV Timing Checks

- OCV Enhancements

- AOCV

- SSTA

- CRPR/CPPR